Grade: A1 (Carbon Steel Rail), A759 (Crane Rail)

All Categories

Structural Steel Sections

Structural Steel Sections

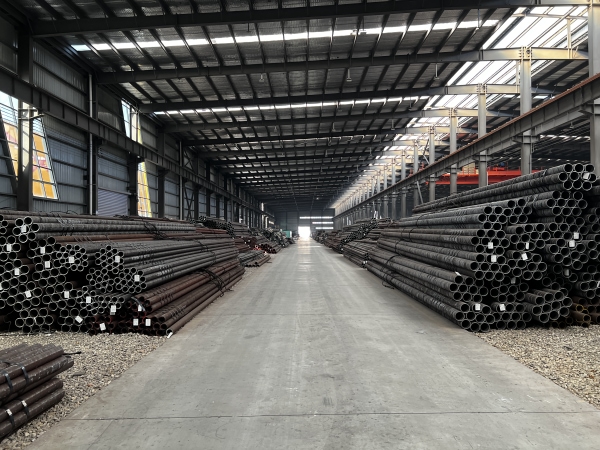

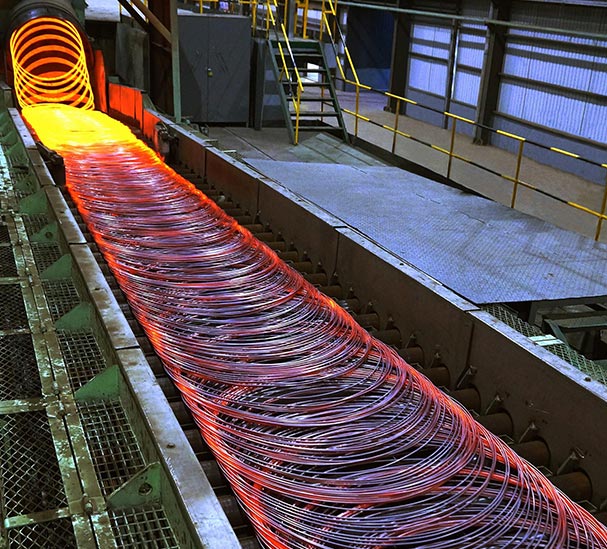

Structural steel is a category of steel used for making construction materials in a variety of shapes. It is primarily composed of iron and carbon, often alloyed with manganese and other elements to enhance strength and durability. The density is typically around 7.85 g/cm³ and the melting point is approximately 1510°C (depending on the alloy). Structural steel possesses high tensile strength, ductility, and toughness, making it indispensable in modern construction. It is widely used in the framework of buildings, bridges, transmission towers, and industrial machinery due to its excellent load-bearing capacity and weldability. It can be hot-rolled or cold-formed into various standardized cross-sectional shapes such as beams, channels, and angles.

Structural Steel Sections Products

| Name | Definition | Features | Size Range | Common ASTM Grades | Main Applications |

|---|---|---|---|---|---|

| Angles Steel | L-shaped cross-section with two legs joined at a 90-degree angle; can be equal or unequal legs. | Versatile, easy to bolt and weld; provides two-way stiffness. | Side Width: 20-200mm Thickness: 3-24mm | A36, A572, A529 | Brackets, framing, shelving, transmission towers, reinforcement trimming. |

| Channel Steel | C-shaped or U-shaped cross-section consisting of a web and two flanges. | Good structural support, ideal for frames where a flat back is needed for mounting. | Height: 50-400mm Leg Width: 25-100mm | A36, A572, A588 | Building frames, vehicle chassis, machinery bases, wall studs. |

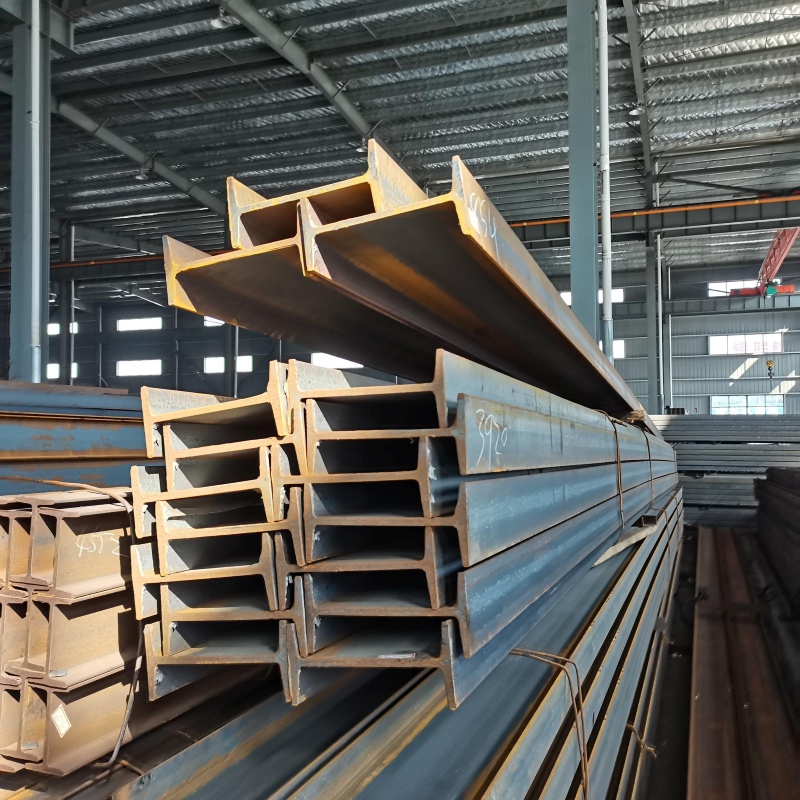

| I-Beam Steel | I-shaped cross-section (often called S-beams) with tapered flanges and a narrower web. | High bending resistance relative to weight; traditional structural shape. | Height: 80-600mm Flange Width: 46-170mm | A36, A572, A992 | Hoist tracks, elevators, trailer beds, structural support for lighter loads. |

| H-Beam Steel | H-shaped cross-section (Wide Flange beams) with parallel flanges that are wider than I-beams. | Superior load distribution, high strength-to-weight ratio; handles shear and bending well. | Height: 100-900mm Flange Width: 100-300mm | A992, A572, A709 | Columns, main beams in skyscrapers, bridges, piling. |

| T-Bar Steel | T-shaped cross-section, essentially a beam split longitudinally. | Lightweight, strong in tension, good surface area for attachment. | Width/Height: 20-150mm Thickness: 3-15mm | A36, A572 | Trusses, ceiling suspension grids, window frames, machinery stiffeners. |

| Steel Rails | Specialized profile with an asymmetric I-shape designed for rolling loads (head, web, foot). | Extreme wear resistance, high hardness, high compressive strength. | Weight typically 8-60 kg/m (Light to Heavy rail) | A1 (Carbon Steel Rail), A759 (Crane Rail) | Railway tracks, subway lines, crane runways, mine cart tracks. |

Structural Steel Standards Comparison

| USA (ASTM) | China (GB) | Europe (EN) | International (ISO) | Main Composition | Characteristics |

|---|---|---|---|---|---|

| A36 | Q235B | S235JR | E235B | C ≤ 0.26%, Mn, P, S | Low carbon ("mild") steel. Good weldability and machinability. The standard for general structural applications like angles and channels. |

| A572 Gr.50 | Q355B (formerly Q345) | S355JR | E355 | Low Carbon, V/Cb/Nb alloys | High-strength low-alloy (HSLA) steel. Higher yield strength (50 ksi/345 MPa) allowing for lighter structure weights. Common for beams. |

| A992 | Q355 | S355 | - | C, Mn, Si, V, Cu | The standard grade for Wide Flange (H-beams) in the US. Excellent ductility and weldability with 50 ksi min yield strength. |

| A588 | Q355GNH | S355J0W | - | Cu, Cr, Ni, P | "Weathering steel" (Corten equivalent). Forms a protective rust patina. Corrosion-resistant, used in bridges and exposed structures. |

| A709 | Q345q | S355 | - | - | Standard strictly for bridge steel. Available in various strength grades (36, 50, 50W). High impact toughness requirements. |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom products in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released