Grade: A53 (A/B), A106, A153 (Zinc coating spec)

All Categories

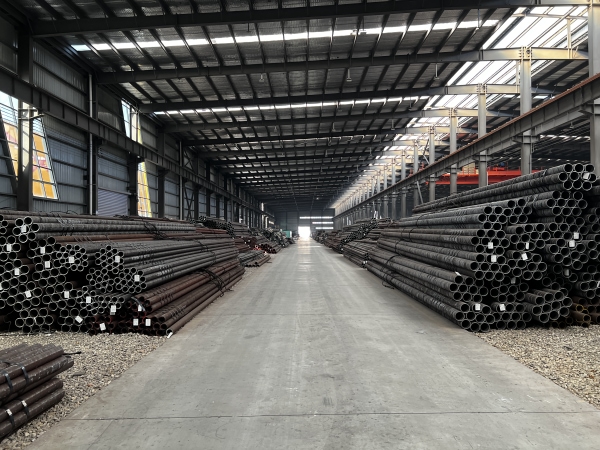

Steel Pipes & Tube

Steel Pipes & Tube

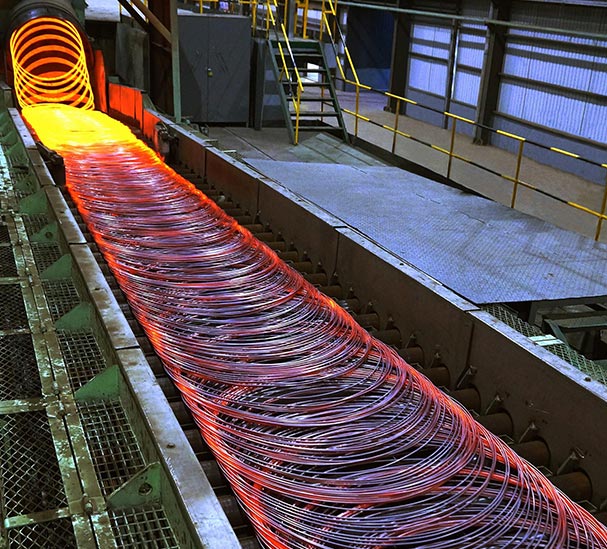

Steel pipes and tubes are hollow sections with a circular or geometric cross-profile used to convey fluids, gases, or serve as structural elements. Manufactured primarily from carbon steel or alloy steel, these products are characterized by their high strength-to-weight ratio, uniformity, and ability to withstand high pressure. Steel pipes are dimensionally defined by Nominal Pipe Size (NPS) and schedule (wall thickness), while tubes are typically defined by exact outside diameter (OD) and wall thickness. They are essential in infrastructure, including oil and gas pipelines, water distribution, construction frameworks, and mechanical systems. The manufacturing methods include seamless (extruded or drawn), welded (ERW, LSAW, SSAW), and subsequent surface treatments like galvanizing or cold drawing for precision.

Steel Pipes & Tube Products

| Name | Definition | Features | Size Range | Common ASTM Grades | Main Applications |

|---|---|---|---|---|---|

| Seamless Steel Pipe | Manufactured without welding seams by piercing a solid billet and rolling it to size. | Uniform structure, withstands high pressure, superior corrosion resistance, no weak points. | OD: 10mm–720mm Wall Thickness: 2mm–65mm Schedules: Sch 40–160 | A106 (B/C), A53 (B), A335 (P11/P22) | Oil & gas pipelines, high-pressure boilers, chemical equipment, machinery parts. |

| Welded Steel Pipe | Formed from flat steel strip or plate and welded longitudinally or helically (ERW, LSAW, SSAW). | Cost-effective, available in long lengths, wide diameter range, consistent dimensions. | OD: 10mm–4,000mm Wall Thickness: 1.5mm–50mm Length: up to 18m | A53 (A/B), A252, A500, API 5L (GR.B/X42/X52) | Water transmission, structural columns, piling, low-pressure fluid transport. |

| Galvanized Steel Pipe | Carbon steel pipe coated with a protective layer of zinc by hot-dip or electro-galvanizing. | Excellent corrosion/rust resistance, long service life, lower maintenance costs. | OD: 15mm–200mm (NPS 1/2"–8") Wall Thickness: 2mm–10mm | A53 (A/B), A106, A153 (Zinc coating spec) | Plumbing systems, fencing, outdoor structures, greenhouse frames, scaffolding. |

| Cold Drawn Precision Steel Tube | Hot-rolled tube processed through cold drawing dies for tight tolerances and smooth finish. | High dimensional accuracy (h9–h11), smooth surface, excellent machinability, enhanced strength. | OD: 6mm–100mm Wall Thickness: 0.5mm–20mm Tolerance: ±0.05–0.10mm | A519 (1020/1026/4130), A106 | Hydraulic cylinders, automotive components, precision machinery, shock absorbers. |

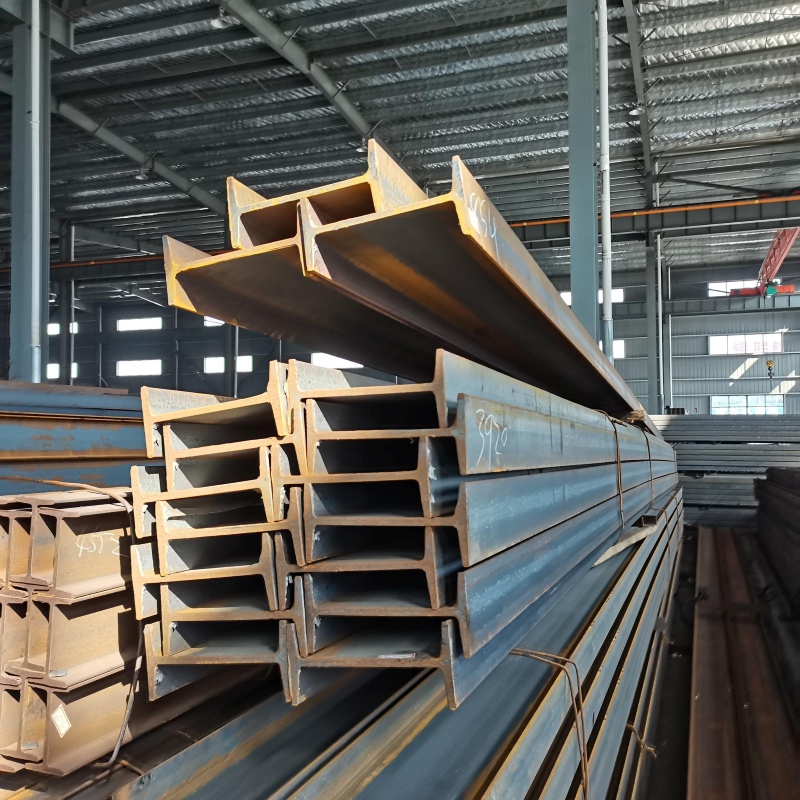

| Steel Square Tube | Hollow structural section (HSS) with a square cross-profile, formed by welding or cold-forming. | High torsional resistance, uniform strength in both axes, clean aesthetic appearance. | Size: 10×10mm–400×400mm Wall Thickness: 0.8mm–20mm | A500 (B/C), A36, A847 (Weathering) | Structural frames, gate construction, furniture, sign posts, mechanical supports. |

| Steel Rectangular Tube | Hollow structural section with rectangular cross-profile, providing directional strength. | Efficient load distribution, wide surface for mounting, high strength-to-weight ratio. | Size: 20×10mm–500×300mm Wall Thickness: 1mm–25mm | A500 (B/C), A36, A500 | Building frameworks, bridges, truck beds, conveyor systems, architectural supports. |

Steel Pipes & Tube Standards Comparison

| USA (ASTM) | China (GB) | Europe (EN) | International (ISO) | Main Composition | Characteristics |

|---|---|---|---|---|---|

| A53 (A/B) | Q235 / 20# | S235JR | A53 equivalent | C ≤ 0.30%, Mn ≤ 1.2%, P/S limits | Standard carbon steel pipe for general use. Black and hot-dipped zinc-coated. Used for welding and pressure applications. |

| A106 (B/C) | 20G / 20# | P235GH / P265GH | Seamless Pipe | C: 0.27–0.35%, Mn: 0.29–1.06% | Seamless carbon steel for high-temperature service. Higher temp rating than A53. Used for boilers and process piping. |

| A500 (B/C) | Q235 / Q345 | S235JR / S355JR | Hollow Sections | Low Carbon, Mn content varies | Standard for structural tubing (square/rectangular). High yield strength (46 ksi min for B). Cold-formed welded. |

| API 5L (B/X52/X65) | L245 / L360 / L450 | L245NB / L360NB | API Spec 5L | C/Mn control, P/S low, V/Nb optional | Line pipe specification for oil & gas. Graded by yield strength (B=35 ksi, X52=52 ksi). Critical for transmission pipelines. |

| A519 (1020/4130) | 20# / 30CrMo | E235 / 25CrMo4 | Technical Tubes | 1020: Low C; 4130: Cr 0.8–1.1%, Mo 0.15–0.25% | Seamless mechanical tubing. 1020 for general use; 4130 (Chromoly) for high strength/weight ratio. Aircraft & racing applications. |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom products in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released