Grade: ASTM A228 (Music Wire), SAE 1018, SAE 1050+

All Categories

Steel Wire Rods

Steel Wire Rods

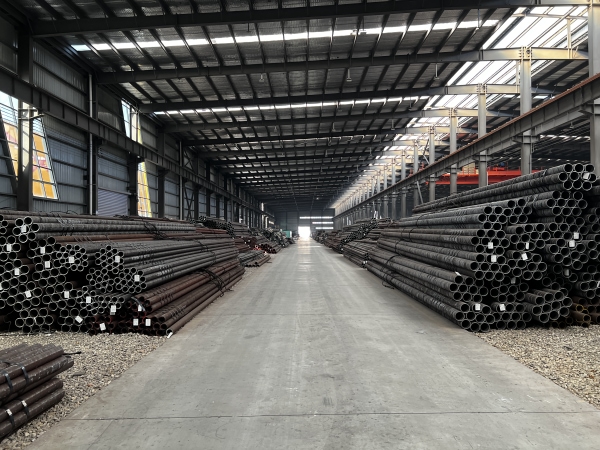

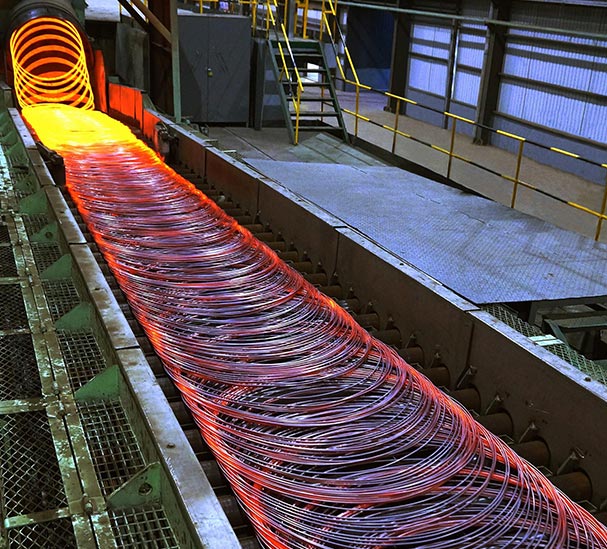

Steel wire rod is a semi-finished long product with a typically circular cross-section, hot-rolled from steel billets in a continuous rolling mill. It serves as the primary raw material for the cold drawing process to produce various types of wires. These rods are usually coiled for transport. While the base density and melting point are consistent with standard steel (~7.85 g/cm³, ~1510°C), the specific mechanical properties—such as ductility, tensile strength, and drawability—are carefully controlled by adjusting the chemical composition (especially carbon content) and the final cooling rate. Wire rods are essential for the production of fasteners, reinforcement mesh, springs, electrical conductors, and high-performance cables.

Steel Wire Rods Products

| Name | Definition | Features | Size Range | Common Grades | Main Applications |

|---|---|---|---|---|---|

| Low Carbon Steel Wire Rod | Rod made from low-carbon steel (C < 0.25%). | Excellent ductility, highly suitable for cold drawing, good weldability, soft. | Standard Diameter: 5.5 - 16 mm | SAE 1006, 1008, Q195 | Nails, wire mesh, galvanized wire, bailing wire, ordinary fasteners, general construction binding wire. |

| High Carbon Steel Wire Rod | (HCSWR) Rod made from medium-to-high carbon steel (C > 0.40%). | Higher tensile strength and hardness; suitable for applications requiring resilience and strength. | Standard Diameter: 5.5 - 14 mm | SAE 1045, 1060, 1070 | Spring wire, pre-stressed concrete wire, tire cord, wire rope, high-strength cable. |

| High Speed Steel Wire Rod | Rod made from specialized tool steel alloys (HSS), containing high amounts of W, Mo, V, Cr. | Exceptional red hardness (maintains hardness at high temperature) and high wear resistance after heat treatment. | Diameter: 6.0 - 20 mm | T1, M2, M42 (Tool Steel Grades) | Raw material primarily for manufacturing high-quality cutting tools (e.g., drill bits, taps, end mills) that require a wire or rod form. |

| Cold Drawn Steel Wire | (Derived Product) Finished wire produced by pulling wire rod through dies, which reduces diameter and increases strength. | Precise dimensional accuracy, smooth surface finish, significantly increased tensile strength through work hardening. | Finished Diameter: 0.1 mm - 10 mm | ASTM A228 (Music Wire), SAE 1018, SAE 1050+ | Springs (critical and non-critical), steel wool, high-strength screws and bolts (cold heading). |

Steel Wire Rods Standards Comparison

| USA (ASTM/SAE) | China (GB) | Europe (EN) | International (ISO) | Carbon Content Range (Approx.) | Characteristics |

|---|---|---|---|---|---|

| SAE 1008 | Q195 / Q215 | C4D / C6D | C4D | 0.05% - 0.10% | Ultra-low carbon content, minimum impurities. Excellent processability (drawability and coating). Used for general purpose wires. |

| SAE 10B21 | ML20MnB | 20MnB4 | - | 0.18% - 0.23% (plus Boron) | Boron-added alloy steel. Improves hardenability and allows for high strength after cold forging and tempering. Used for high-grade fasteners. |

| SAE 1045 | 45# / Q275 | C45 | C45 | 0.42% - 0.50% | Medium carbon grade. Good balance of strength, hardness, and toughness. Requires heat treatment for spring applications. |

| SAE 1070/1080 | 65#/70# | C70D/C80D | C70D/C80D | 0.65% - 0.85% | Used for high-strength requirements. Key raw material for manufacturing piano wire, stranded wire, and concrete wire. |

| ASTM F228 | HSS Rod Standards | DIN 1.3343 (M2) | - | High Alloy (%W, %Mo, %V) | Very high alloy content provides necessary attributes for tool steel applications. Requires strict control over inclusions and homogeneity. |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom products in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released