Grade: A36, A572, A58, 1018

All Categories

Steel Bars

Steel Bars

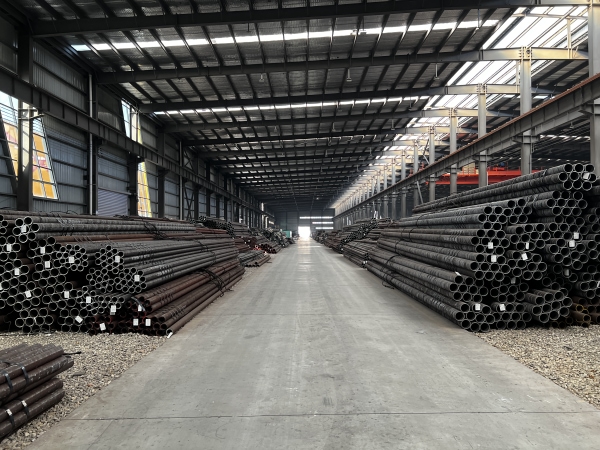

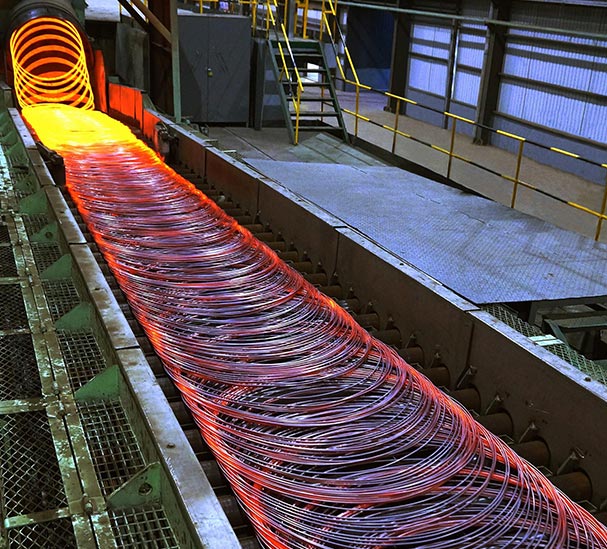

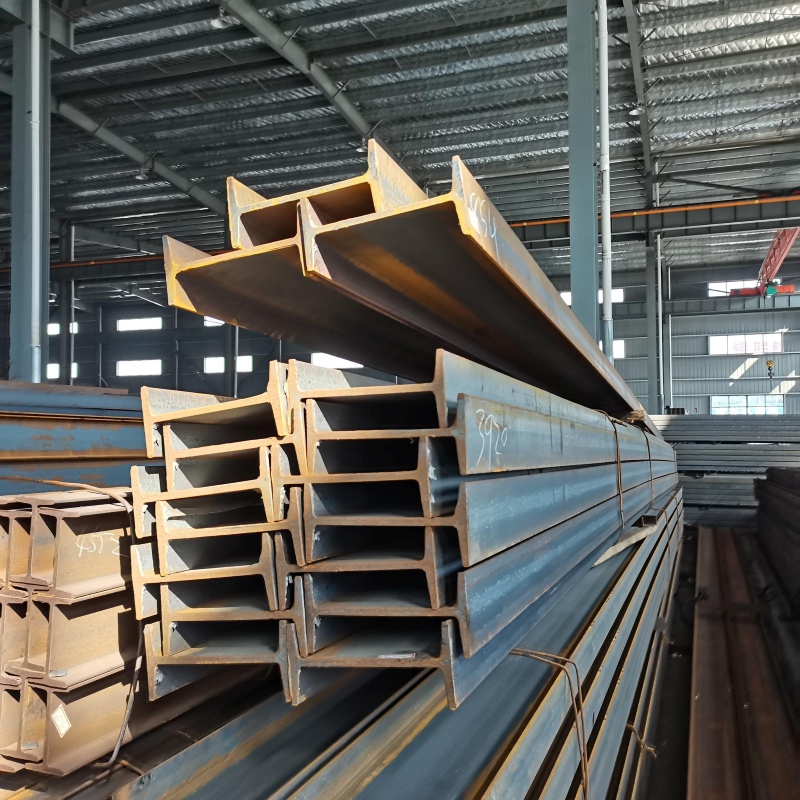

Steel bars are solid, elongated metal sections with uniform cross-sectional profiles, manufactured by hot rolling, cold drawing, or forging processes. Composed primarily of iron and carbon (ranging from low carbon 0.05% to high carbon 0.8% or more), they often contain alloying elements like manganese, chromium, and silicon to enhance mechanical properties. Steel bars exhibit high tensile strength, ductility, and excellent machinability, making them fundamental raw materials in manufacturing and construction. They serve as the primary feedstock for machined components, structural reinforcement, and fabrication applications. The density is approximately 7.85 g/cm³ and melting point varies from 1425°C to 1510°C depending on carbon content and alloy composition.

Steel Bars Products

| Name | Definition | Features | Size Range | Common ASTM Grades | Main Applications |

|---|---|---|---|---|---|

| Steel Round Bar | Solid cylindrical steel bar with a circular cross-section; available in hot-rolled, cold-finished, or forged conditions. | High symmetry, uniform mechanical properties in all directions, excellent for machining and surface hardening. | Diameter: 5mm–300mm (hot-rolled) Diameter: 2mm–50mm (cold-drawn) Length: 4m–12m | A36, A572, A105, 4140, 1045 | Shafts, axles, bolts, pins, gears, general machining stock, automotive components. |

| Steel Square Bar | Solid steel bar with a square cross-section and sharp or slightly rounded corners; produced by hot rolling or cold drawing. | Four-sided profile provides good gripping surfaces, stable stacking, efficient torque transmission. | Side: 6mm–200mm Length: 3m–12m | A36, A105, 1018, 1045 | Architectural fixtures, gate construction, machine bases, furniture frames, ornamental work. |

| Steel Flat Bar | Flat, rectangular steel section with width significantly greater than thickness; sheared from plate or hot-rolled. | Versatile fabrication material, broad surface area for welding, high strength-to-width ratio, easy cutting. | Width: 10mm–400mm Thickness: 3mm–60mm Length: 4m–12m | A36, A572, A58, 1018 | Brackets, base plates, frame construction, truck beds, conveyor systems, machine guards. |

| Hexagonal Steel Bar | Six-sided polygonal steel bar with equal sides and angles; manufactured by cold drawing or hot rolling. | Excellent for wrench tightening, precise positioning, anti-rotation properties, uniform stress distribution. | Across Flats: 5mm–100mm Length: 3m–6m | 1018, 1045, 12L14, A36 | Fasteners (nuts/bolts), precision machinery parts, valve stems, tool shanks, decorative elements. |

| Octagonal Steel Bar | Eight-sided steel bar with equal sides and 135° interior angles; specialized cold-drawn profile. | Combines torque resistance with reduced corner stress compared to squares, aesthetic appeal. | Across Flats: 10mm–80mm Length: 3m–6m | 1018, 1045, A36 | Ornamental railing, special fasteners, precision tools, decorative architectural elements, aerospace fittings. |

| Deformed Steel Reinforcing Bar (Rebar) | Steel bar with surface deformations (ribs, lugs) to enhance mechanical bonding with concrete. | High tensile strength (typically 40–75 ksi yield), superior concrete bond, corrosion-resistant coatings available. | Diameter: 6mm–50mm (#2–#18) Standard Lengths: 6m, 9m, 12m, 18m | A615 (40/60/75), A706, A996, A955 | Concrete reinforcement in buildings, bridges, roads, foundations, retaining walls, seismic-resistant structures. |

Steel Bars Standards Comparison

| USA (ASTM) | China (GB) | Europe (EN) | International (ISO) | Main Composition | Characteristics |

|---|---|---|---|---|---|

| A36 | Q235B | S235JR | E235B | C: 0.18–0.28%, Mn: 0.6–1.0%, P/S ≤ 0.05% | Low carbon structural steel. Most common for general fabrication, welding, and forming applications. Good balance of strength and ductility. |

| 1018 | 20# | C22 / 1.0402 | C22E | C: 0.14–0.20%, Mn: 0.6–0.9%, Low C-Mn | Low-carbon mild steel. Excellent machinability, case hardening capability, smooth cold-drawn finish. The standard for cold-finished bars. |

| 1045 | 45# / 45钢 | C45 / 1.0503 | C45E | C: 0.42–0.50%, Mn: 0.6–0.9%, Medium Carbon | Medium carbon steel. Higher strength and hardness than 1018. Can be heat treated (quenched/tempered). Used for shafts and wear parts. |

| 4140 | 42CrMo | 42CrMo4 / 1.7225 | 42CrMo4 | C: 0.38–0.43%, Cr: 0.9–1.2%, Mo: 0.15–0.25% | Chromium-molybdenum alloy steel. High fatigue strength, toughness, torsional strength. Heat treatable for heavy-duty applications like axles and gears. |

| A615 (Gr.40/60/75) | HRB335 / HRB400 / HRB500 | B500B | B500B | C: 0.26–0.40%, Mn: 0.6–1.0%, Si: 0.15–0.40% | Standard carbon steel rebar. Grade numbers indicate yield strength (40 ksi/60 ksi/75 ksi). Ribbed surface pattern for concrete adhesion. Weldable with precautions. |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom products in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released